Last updated: 8/26/20

Nancy LT Hamilton, Author

These tools are fabulous for finishing any area that has texture, pattern, hard-to-reach nooks and crannies, deep folds, etc. I love them for cleaning up stone settings like the basket setting.

They will cut grooves into smooth material – if you don’t take care. For flat, smooth metal, I prefer sanding discs, sandpaper, or a belt sander.

Don’t forget to stack the discs. Stack 3 to 6 on top of one another.

Also, don’t forget to have the bristles pointing in the correct direction. Mine point in a clockwise direction. If your flex shaft is in reverse, they will be facing the other way. Why is your flex shaft in reverse, BTW? I’m just confused!

You can get different sized mandrels too! I have a quick change handpiece so, I like all my mandrels to be 3/32″. If you don’t care, you can use the 1/8″ mandrels. Just be sure that the screw fits into your discs! The 9/16″ and 3/4″ discs have a 1/16″ inch hole and the 1″ disc has a 1/8″ hole. So exciting!

You can get different sized mandrels too! I have a quick change handpiece so, I like all my mandrels to be 3/32″. If you don’t care, you can use the 1/8″ mandrels. Just be sure that the screw fits into your discs! The 9/16″ and 3/4″ discs have a 1/16″ inch hole and the 1″ disc has a 1/8″ hole. So exciting!

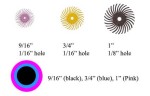

There are three smaller sizes of radial bristle discs for use with flex shafts, micromotors, or Dremels. The discs come in sizes: 9/16″, 3/4″ and 1″. I generally use the 3/4″ as an all-around size. The 9/16″ are teeny and I find the 1″ a bit large but, it all depends on what you are using them for and your likes and needs.

Visual comparison of 9/16″, 3/4″ and 1″ Bristle Discs:

Here’s another chart. This one shows colors and their associated grits.

You can also purchase larger discs for your buffing motor.

These discs are great for woodworking and carvers will appreciate their ability to reach into small, recessed areas.

Further Reading

- Here’s some more information from the manufacturer: Bristle Discs and Brushes

- Ganoksin, Mark B. Mann, The 3M® Radial Bristle Disc Proficiency Advantage, Web. 2004.